![[field:title/]](/uploads/1905/1-1Z52914412Y41.png)

| 客服热线:0512-80606568 |

|

English |

| 客服热线:0512-80606568 |

|

English |

颚式破碎机

![[field:title/]](/uploads/1905/1-1Z52914412Y41.png)

|

破碎机规格 Model |

MJ4090 | MJ4120 | MJ6120 | MJ6130 | MJ6150 | MJ8150 |

|

给料口(mm) Feeding Size |

895×660 | 1200×830 | 1200×1100 | 1300×1130 | 1500×1070 | 1500×1300 |

| L=最大长度(m) | 2.55 | 3.23 | 3.61 | 3.76 | 4.11 | 4.50 |

| W=最大宽度(m) | 1.88 | 2.57 | 2.35 | 2.47 | 3.00 | 2.90 |

| H=最大高度(m) | 2.38 | 2.95 | 3.51 | 3.85 | 3.33 | 4.19 |

| D=飞轮直径(m) | 1.60 | 1.86 | 1.86 | 2.17 | 1.76 | 2.17 |

| F=给料高度(m) | 1.58 | 1.93 | 2.50 | 2.68 | 2.39 | 3.05 |

| 发运体积(m³) | 13 | 23 | 32 | 38 | 48 | 58 |

|

排料矿口范围(mm) (CSS)Range |

50-175 | 75-275 | 125-275 | 125-300 | 125-300 | 150-300 |

|

破碎机重量(kg) Weight |

13200 | 27000 | 34500 | 41500 | 53000 | 63500 |

|

电动机功率(kw) Motor Power |

75 | 132 | 160 | 160 | 200 | 200 |

|

生产能力(t/h) Capacity |

85-320 | 240 | 305-800 | 330-965 | 385-1090 | 480-1155 |

|

紧边排矿口CSS (mm) |

破碎机型号 Model | |||||

| MJ4090 | MJ4120 | MJ6120 | MJ6130 | MJ6150 | MJ8150 | |

| 40 | ||||||

| 50 | 85-115 | |||||

| 75 | 95-155 | 160-220 | ||||

| 100 | 120-195 | 220-295 | ||||

| 125 | 145-230 | 270-350 | 3295-390 | 330-435 | 385-495 | |

| 150 | 170-270 | 320-435 | 355-460 | 385-500 | 440-595 | 480-620 |

| 175 | 195-315 | 390-510 | 400-525 | 445-570 | 505-670 | 540-705 |

| 200 | 440-575 | 450-590 | 490-645 | 575-745 | 615-805 | |

| 225 | 490-645 | 505-665 | 550-735 | 635-820 | 670-880 | |

| 250 | 555-725 | 555-730 | 605-805 | 705-925 | 745-980 | |

| 275 | 605-795 | 605-800 | 660-880 | 770-1005 | 825-1060 | |

| 300 | 720-965 | 820-1080 | 880-1155 | |||

上表中给出的产量只是说明破碎机能力的一个近似值。所对应的条件是开路破碎,物料容重为1600 kg/m3 干燥的爆 破花岗岩,其最大尺寸满足破碎机允许的最大给料粒度。表中较低的值适用于给料中小于排矿口尺寸的细料被剔除的 情况,较高的值则适用于含有细料的情况。破碎机可以正常运行的最小紧边排矿口取决于给料的粒度分布、材料的可 碎性(Wi)、给料中污染物的含量、所安装的颚板类型及其材料种类等。

The capacity shown in the table only indicates an approximation of the capacity of the crusher. The corresponding condi- tions are open-circuit crushing, dry blasting granite with a bulk density of 1600 kg/m3, the maximum size of which can meet the maximum feed size allowed by the crusher. The lower values in the table apply to the circumstance where the fines of the feeding less than the size of the discharge are rejected, and the higher values apply to the circumstance with contents of fines. The CSS that the crusher can operate normally depends on the feeding granularity distribution, the friability of the material (Wi), the amount of feeding contaminants, the type of jaw plates installed, and the type of its material used.

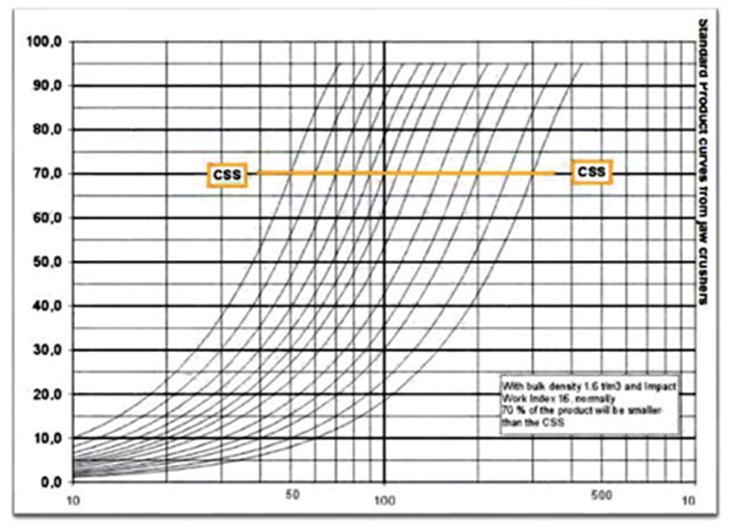

排料粒度特性曲线 本曲线为中等可碎岩石(破碎功指数Wi=16)的典型粒度特性曲线, 在破碎产品中,约有75%的产品小于紧边排矿口(CSS)。 粒度曲线的形状和产品小于破碎机紧边排矿口(CSS)的比例,取决于 原料的特性。对于可碎性不同的岩石(Wi在20-12之间),通常其破碎 产品中大约有65%-85%小于破碎机的紧边排矿口。

The Characteristic Curve of Discharge Granularity This curve is a typical granularity characteristic curve of medium crushable rock (Crush- ing Work Index Wi=16). About 75% of the products are less than the CSS. The shape and product of the Granularity Curve is less than the ratio of the CSS, depending on the characteristics of the minerals. For rocks with different friability (Wi between 20-12), normally about 65%-85% of the crushed product is less than the crusher CSS.